Efficient fluid transfer and precise control are essential in numerous industries, and the integration of ODM peristaltic pumps, peristaltic pump controllers, and peristaltic heads offers a comprehensive solution. ODM peristaltic pumps provide customized solutions for diverse fluid transfer requirements, while peristaltic pump controllers enhance control and automation capabilities.

ODM Peristaltic Pump: Customized Solutions for Fluid Transfer

ODM peristaltic pumps, also known as Original Design Manufacturer peristaltic pumps, offer customized solutions tailored to specific fluid transfer requirements. These pumps are designed to provide reliable, accurate, and repeatable performance in a wide range of applications. ODM peristaltic pumps are known for their versatility, allowing customization of parameters such as flow rates, tubing sizes, materials, and motor types. This flexibility ensures compatibility with various fluids, from corrosive chemicals to sensitive biological samples. ODM peristaltic pumps find application in industries such as pharmaceutical manufacturing, food and beverage, and water treatment, offering efficiency, ease of use, and precise control over fluid transfer.

Peristaltic Pump Controller: Enhanced Control and Automation

A peristaltic pump controller is a key component that complements the peristaltic pump system by providing enhanced control and automation capabilities. These controllers offer precise control over flow rates, direction, and timing, allowing for accurate and reproducible fluid transfer. Peristaltic pump controllers feature intuitive interfaces and programmable functionality, enabling users to set parameters, create complex pumping sequences, and integrate with other equipment or systems. The ability to control multiple pumps simultaneously enhances efficiency and productivity in applications that require coordinated fluid transfer. Peristaltic pump controllers are widely used in research laboratories, bioprocessing, and industrial automation, providing seamless integration and advanced control options for peristaltic pumping systems.

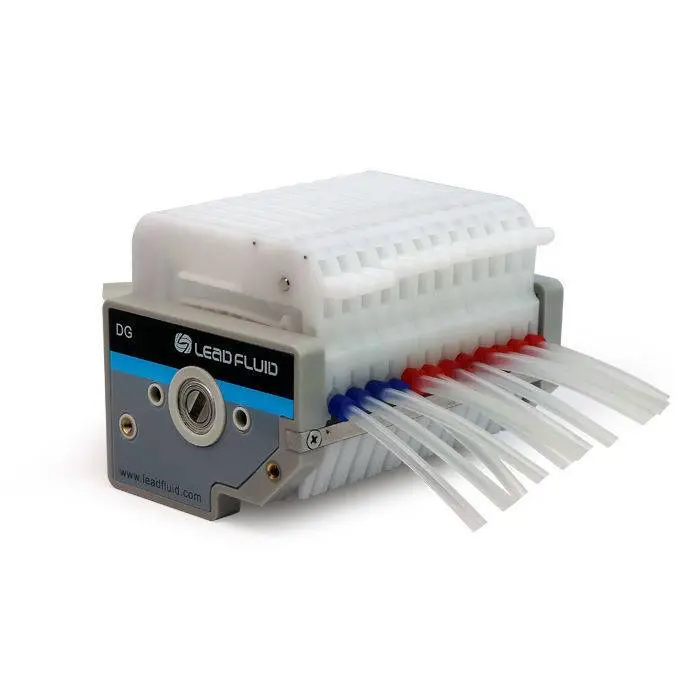

Peristaltic Head: Key Component for Fluid Interaction

The peristaltic head by China odm peristaltic pump suppliers, also known as the pump head or tubing assembly, is a critical component that directly interacts with the fluid being transferred. It consists of a housing and a tube holder mechanism that compresses the flexible tubing to create the peristaltic motion for fluid transfer. The design of the peristaltic head ensures proper occlusion and prevents fluid leakage or contamination. The tubing used in the peristaltic head plays a vital role in determining the pumping efficiency and compatibility with various fluids. The selection of tubing materials, sizes, and wall thicknesses is crucial to match the application requirements, such as chemical resistance, pressure compatibility, and temperature range. Peristaltic heads are available in various configurations, including single-channel and multi-channel designs, allowing for simultaneous fluid transfer and versatility in application setups. These heads are frequently used in biomedical research, diagnostics, and pharmaceutical manufacturing, where precise and contamination-free fluid transfer is essential.

Advantages and Considerations

The integration of ODM peristaltic pumps, peristaltic pump controllers, and peristaltic heads offers several advantages:

Customization: ODM peristaltic pumps provide tailored solutions to match specific application requirements, ensuring optimal performance and efficiency.

Control and Automation: Peristaltic pump controllers enable precise control and automation, allowing for accurate flow rates, sequencing, and integration with other equipment or systems.

Reliable Fluid Transfer: Peristaltic heads ensure reliable and contamination-free fluid transfer, with options for single-channel or multi-channel configurations to accommodate various application setups.

When considering these components, factors such as flow rate range, accuracy, tubing compatibility, maintenance requirements, and cost should be evaluated to select the most suitable solution for the desired application.