Fluid control is a crucial aspect of many industries, ranging from pharmaceuticals to research laboratories. Achieving precise and accurate flow rates is essential for maintaining product quality and process efficiency. In this article, we delve into the advantages of flow rate pumps, peristaltic tube pumps, and dual syringe pumps in optimizing fluid control.

What is A Flow Rate Pump ?

A flow rate pump, also known as a flow pump or simply a pump, is a device used to move fluids from one place to another. The flow rate of a pump refers to the volume of fluid that the pump can move per unit of time. It is typically measured in units such as liters per minute (L/min), gallons per minute (GPM), or cubic meters per hour (m³/h).A flow rate pump is a device that moves fluids and its flow rate refers to the volume of fluid it can move per unit of time. The flow rate of a pump is an important consideration when selecting a pump for a specific application.

Flow Rate Pumps : Tailored Flow Control

Flow rate pumps are designed to provide precise control over the rate at which fluids are dispensed. These pumps offer adjustable flow rates, allowing users to tailor the pumping speed to meet specific application requirements. Flow rate pumps find applications in industries such as chemical processing, water treatment, and food production, where accurate flow control is critical. By maintaining consistent flow rates, these pumps ensure product quality, process efficiency, and regulatory compliance.

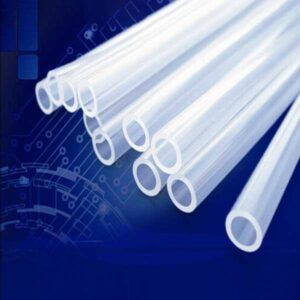

Peristaltic Tube Pumps : Gentle and Versatile Fluid Handling

Peristaltic tube pumps utilize a rotating roller mechanism to gently squeeze and release a flexible tube, creating a pumping action. This design offers several advantages, including gentle fluid handling, minimal risk of contamination, and versatility in handling different types of fluids. Peristaltic tube pumps are widely used in industries such as pharmaceuticals, biotechnology, and research laboratories, where precise and contamination-free fluid transfer is essential. These pumps are particularly suitable for sensitive fluids, as they do not come into direct contact with the pump components.

Dual Syringe Pumps : Precise Control of Dispensing Simultaneously

Dual syringe pumps are designed to dispense fluids from two separate syringes simultaneously. This configuration enables precise and controlled dispensing of two different fluids or the mixing of two fluids in a controlled ratio. Dual syringe pumps are commonly used in applications such as analytical chemistry, drug delivery, and microfluidics, where precise and simultaneous fluid dispensing is required. These pumps offer high accuracy, repeatability, and the ability to program complex dispensing sequences, making them invaluable in various scientific and medical research settings.

Application of Dual Syringe Pumps

Dual syringe pumps, as the name suggests, are pumps that utilize two syringes to deliver fluids. These pumps are commonly used in various scientific and laboratory applications where precise and controlled fluid delivery is required. Some of the applications of dual syringe pumps include:

- Analytical Chemistry: Dual syringe pumps are often used in analytical chemistry for sample preparation and analysis. They can be used for precise mixing of reagents, dilution of samples, and delivery of standards or calibration solutions.

- Drug Discovery and Development: Dual syringe pumps are used in pharmaceutical research and development processes. They are employed for accurate and controlled delivery of drug compounds, testing formulations, and studying drug interactions.

- Microfluidics: Dual syringe pumps are essential in microfluidic systems, which involve the manipulation and control of small volumes of fluids. They are used for precise fluid delivery in microfluidic experiments, such as cell studies, DNA analysis, and chemical reactions on a microscale.

- Biotechnology and Life Sciences: Dual syringe pumps find applications in biotechnology and life sciences research. They are used for controlled delivery of reagents, enzymes, and buffers in experiments involving DNA sequencing, protein analysis, cell cultures, and other molecular biology techniques.

- Industrial Automation: Dual syringe pumps can be used in industrial automation processes that require accurate and controlled fluid dispensing. They can be integrated into automated systems for tasks such as filling vials, dispensing adhesives or coatings, and controlling fluid flow in manufacturing processes.

Fluid control plays a vital role in numerous industries, and the ability to optimize flow rates is crucial for maintaining product quality and process efficiency. Flow rate pumps provide tailored flow control, allowing users to adjust the pumping speed to meet specific application requirements. Peristaltic tube pumps offer gentle and versatile fluid handling, minimizing the risk of contamination and ensuring precise fluid transfer. Dual syringe pumps enable simultaneous and controlled dispensing of two fluids, making them ideal for applications that require precise mixing or sequential dispensing. As technology continues to advance, businesses and industries can expect further enhancements in fluid control, leading to improved productivity, accuracy, and reliability.