Peristaltic pumps have long been prized for their precise and contamination-free fluid transfer capabilities, making them indispensable in various industries, including pharmaceuticals, biotechnology, and food processing. Within the realm of peristaltic pumps, there have been significant advancements in tubing connectors and the development of dual head peristaltic transfer pumps. This article explores the innovations and applications of peristaltic pump tubing connectors, dual head peristaltic pumps, and peristaltic transfer pumps.

The Peristaltic Pump and Its Mechanism

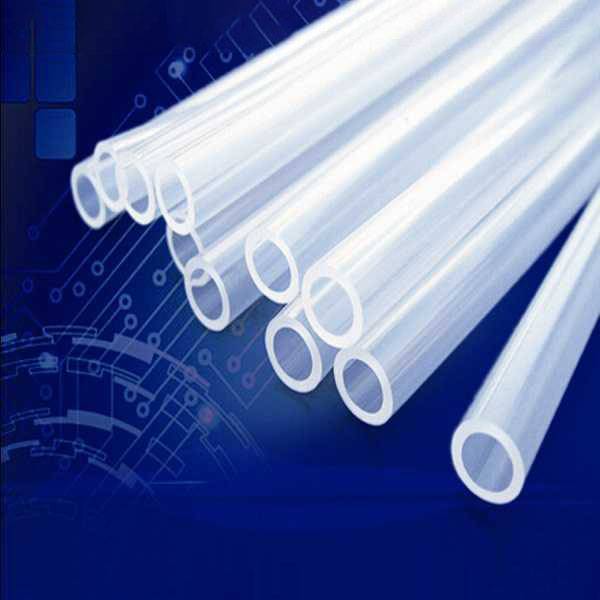

Peristaltic pumps operate on a simple yet effective mechanism. A flexible tube is compressed by rollers or shoes within the pump head, creating a series of isolated segments. As these segments move, they squeeze the fluid within the tube, propelling it through the tubing. The key advantage of this mechanism is that the fluid remains completely contained within the tubing, preventing contamination and ensuring precise dispensing.

Applications of Peristaltic Pumps

Peristaltic pumps are utilized in a wide range of industries for applications such as chemical dosing, bioprocessing, food and beverage production, and medical equipment. They are especially valuable when handling sensitive or corrosive fluids that can’t come into contact with the pump components.

Peristaltic Pump Tubing Connectors – The Unsung Heroes

- The Importance of Tubing Connectors:Tubing connectors are often overlooked but play a critical role in the performance of peristaltic pumps. They are responsible for securely connecting the tubing to the pump head, ensuring a leak-free and reliable fluid transfer.

- Types of Tubing Connectors:There are various types of tubing connectors available, including barbed connectors, threaded connectors, and quick-connect fittings. The choice of connector type depends on the specific application and the tubing material.

- Advances in Tubing Connector Design:Recent advancements in tubing connector design have focused on improving the ease of use and ensuring compatibility with a wide range of tubing materials. Newer connectors offer quick and secure connections, reducing the risk of leaks and downtime.

Understanding Dual Head Peristaltic Pumps

A dual head peristaltic pump is equipped with two pump heads, each with its own tubing, allowing for the simultaneous transfer of two different fluids. This innovation significantly increases the pump’s versatility and efficiency.

Advantages of Dual Head Peristaltic Pumps

The dual head design enables precision in multi-component dispensing and mixing, making these pumps ideal for applications that require accurate ratios of multiple fluids. They also offer redundancy, ensuring continued operation if one pump head experiences an issue.

Applications of Dual Head Peristaltic Pumps

Dual head peristaltic pumps are used in various applications, including bioprocessing, chemical synthesis, and laboratory automation. They are particularly valuable in pharmaceutical production for the precise dispensing of active ingredients and excipients.

Peristaltic Transfer Pumps – Enabling Safe and Clean Fluid Transfer

- The Role of Peristaltic Transfer Pumps:Peristaltic transfer pumpsare designed specifically for the safe and contamination-free transfer of fluids. They are commonly used in pharmaceutical manufacturing, bioprocessing, and other industries where the integrity of the transferred fluid is of utmost importance.

- Design and Features:Peristaltic transfer pumps are equipped with larger pump heads and tubing, allowing them to handle higher flow rates and volumes. They are designed to minimize shear forces on sensitive fluids, ensuring the preservation of product integrity.

- Applications of Peristaltic Transfer Pumps:These pumps find extensive use in the transfer of shear-sensitive biological materials, pharmaceutical formulations, and food products. Their ability to handle viscous fluids, slurries, and abrasive substances while maintaining sterility is invaluable in various industries.

Real-world Applications

- Pharmaceutical Manufacturing:Explore how dual head peristaltic pumps are utilized in pharmaceutical manufacturing to accurately dispense multiple active ingredients during drug formulation.

- Bioprocessing:Learn how peristaltic transfer pumps are employed in bioprocessing to ensure the sterile and gentle transfer of sensitive biological materials in large-scale production.

- Laboratory Automation:Discover how peristaltic pump tubing connectors enhance the efficiency of laboratory automation systems by providing secure and leak-free connections.

Peristaltic pumps, with their precise and contamination-free fluid transfer capabilities, continue to be indispensable in various industries. The innovations in tubing connectors, dual head peristaltic pumps, and peristaltic transfer pumps have expanded their applications and made them even more reliable and efficient. As technology advances, these pumps are likely to play an increasingly critical role in shaping the future of fluid transfer in industries that demand precision