Peristaltic pumps are widely recognized for their unique pumping mechanism, which involves the compression and relaxation of flexible tubing to move fluids. These pumps offer numerous advantages, including gentle fluid handling, precise flow control, and easy maintenance. In this article, we will delve into three specific aspects of peristaltic pump technology: peristaltic pump tubing connectors, dispensing peristaltic pumps, and peristaltic chemical pumps. By understanding these key features, we can appreciate the versatility and applications of peristaltic pumps in various industries.

Peristaltic Pump Tubing Connectors: Ensuring Secure and Leak-Free Fluid Connections

Peristaltic pump tubing connectors play a crucial role in ensuring a secure and leak-free connection between the pump and the tubing. These connectors are designed to provide a tight seal while allowing for easy tube replacement and maintenance. They come in various configurations, including barbed connectors, luer fittings, and compression fittings, offering compatibility with different tubing materials and sizes. The proper selection of tubing connectors is essential for maintaining the integrity of the fluid path and preventing contamination or leakage.

Dispensing Peristaltic Pump: Precise and Controlled Fluid Dispensing

Dispensing peristaltic pumps are specifically designed for accurate and precise fluid dispensing applications. With programmable control and high repeatability, these pumps offer exceptional accuracy, making them ideal for applications that require precise dosing or filling. They find extensive use in industries such as pharmaceuticals, biotechnology, food and beverage, and laboratory research. Dispensing peristaltic pumps can be integrated with advanced features like flow rate monitoring, volume measurement, and automation, further enhancing their versatility and efficiency.

Applications of Dispensing Peristaltic Pumps

- Laboratory Research: Peristaltic dispensing pumps are widely used in research laboratories for tasks such as pipetting reagents in assays, filling test tubes, and transferring biological samples without risk of cross-contamination. They provide repeatable and programmable flow rates which is crucial for reproducibility in experiments.

- Pharmaceutical Manufacturing: The pharmaceutical industry relies heavily on dispensing peristaltic pumps for accurately measuring and delivering active ingredients, buffers, and solvents during drug formulation processes. This ensures consistency in dosages and eliminates potential errors associated with manual dispensing.

- Food and Beverage Industry: For batching and proportioning liquids like flavors, colors, and preservatives, these pumps offer exceptional precision. They can also handle food-grade materials and meet stringent hygiene standards, thus minimizing waste and ensuring product quality.

- Chemical Processing: In chemical synthesis, cleaning agents, and water treatment plants, peristaltic dispensing pumps can dispense corrosive or abrasive chemicals safely and reliably. Their self-sealing nature prevents any backflow or leakage, protecting both the pump and the operator.

- Medical Devices: From intravenous (IV) therapy to dialysis machines, peristaltic pumps are used to deliver medications, fluids, and blood products with great accuracy. They are also integral parts of various diagnostic equipment, dispensing precise volumes of reagents in automated testing systems.

- Printing and Inkjet Technology: In the printing industry, they’re employed for precise delivery of ink and other colorants, enabling high-resolution prints and uniformity across large print runs.

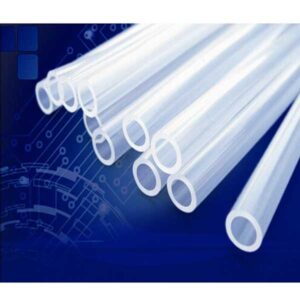

Peristaltic Chemical Pump: Safe and Efficient Fluid Transfer

Peristaltic chemical pumps are engineered to handle aggressive or corrosive fluids safely. These pumps are equipped with chemically resistant tubing materials such as silicone, Viton®, or PTFE, ensuring compatibility with a wide range of chemicals. They are commonly employed in chemical processing, water treatment, and laboratory environments where the controlled transfer of harsh or sensitive fluids is essential. The peristaltic pumping action, combined with the chemically resistant tubing, prevents the fluid from coming into contact with any pump components, ensuring reliable and contamination-free fluid transfer.

Peristaltic pumps offer a versatile and reliable solution for various fluid handling applications. The tubing connectors enable secure connections and easy maintenance, ensuring a leak-free fluid path. Dispensing peristaltic pumps provide accurate and precise fluid dispensing, making them indispensable in industries that require precise dosing or filling. Peristaltic chemical pumps, with their chemically resistant tubing, offer a safe and efficient solution for handling corrosive or sensitive fluids. Whether in laboratory research, industrial processes, or medical applications, peristaltic pumps continue to prove their worth as reliable and versatile fluid handling devices.