Flow rate pumps are essential devices used in various industries to control the flow of liquids or gases. Two popular types of flow rate pumps are micro gear pumps and peristaltic tube pumps. This article delves into the features, benefits, and applications of these pumps, highlighting their importance in fluid handling processes.

Micro Gear Pumps: Precision and Efficiency in Fluid Control

Micro gear pumps are compact and precise devices designed to deliver accurate flow rates in a wide range of applications. These pumps utilize a gear mechanism to create positive displacement, ensuring consistent and reliable fluid control.

One of the key advantages of micro gear pumps is their ability to handle low flow rates with high precision. They are capable of delivering precise volumes of liquid or gas, making them ideal for applications that require accurate dosing or metering. Industries such as pharmaceuticals, chemical processing, and analytical instrumentation benefit greatly from the precision offered by micro gear pumps.

Additionally, micro gear pumps are known for their efficiency and durability. They can handle a wide range of viscosities, from thin solvents to highly viscous fluids, without compromising performance. Their compact size and low power consumption make them suitable for portable or space-constrained applications.

Peristaltic Tube Pumps: Versatility and Gentle Fluid Handling

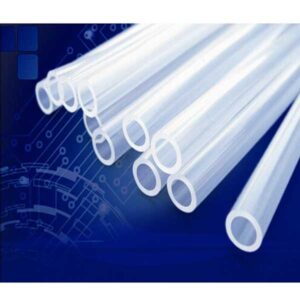

Peristaltic tube pumps, also known as hose pumps, operate on the principle of peristalsis, where a rotating roller compresses and relaxes a flexible tube to create fluid flow. These pumps are widely used in industries that require gentle fluid handling, such as pharmaceuticals, biotechnology, and food processing.

One of the primary advantages of peristaltic tube pumps is their ability to handle delicate or shear-sensitive fluids without causing damage or degradation. The fluid only comes into contact with the tubing, eliminating the risk of contamination or cross-contamination. This makes peristaltic tube pumps suitable for applications that require sterile or hygienic fluid transfer.

Peristaltic tube pumps also offer excellent versatility, as they can handle a wide range of flow rates and viscosities. The flow rate can be easily adjusted by changing the speed of the rotating roller, providing flexibility in various process requirements. Moreover, the tubing used in peristaltic pumps can be easily replaced, ensuring quick and efficient maintenance.

Flow Rate Pump Applications: Diverse Industries and Processes

A flow rate pump is a device that controls and maintains the speed at which fluids move through a system. Here are several applications where flow rate pumps play a crucial role:

- Water Treatment Plants: In water treatment facilities, flow rate pumps are used to regulate the movement of raw water into the purification process and treated water out to distribution networks. They ensure a consistent flow for effective filtration, chemical dosing, and disinfection.

- Chemical Processing Industry: Flow rate pumps are essential in the chemical industry for transferring and metering precise amounts of chemicals in reactors, mixers, and other processing equipment. This control ensures optimal reaction conditions and product quality.

- HVAC Systems: Heating, Ventilation, and Air Conditioning (HVAC) systems employ flow rate pumps in chilled water loops to maintain a constant flow rate for efficient heat transfer. These pumps help regulate the cooling effect in buildings and industrial processes.

- Irrigation Systems: Agriculture relies on flow rate pumps to distribute water evenly across fields, orchards, or greenhouses. The accurate flow control prevents overwatering or underwatering, ensuring crop health and conserving water resources.

Both micro gear pumps and peristaltic tube pumps find applications in a wide range of industries and processes.

Micro gear pumps are commonly used in chemical dosing, fuel injection systems, inkjet printing, and laboratory research. Their precise flow control and compatibility with different fluids make them invaluable in these applications.

Peristaltic tube pumps are widely employed in pharmaceutical manufacturing, bioprocessing, wastewater treatment, and food and beverage production. Their gentle fluid handling capabilities and sanitary design make them suitable for critical processes that require accurate and contamination-free fluid transfer.

Flow rate pumps, including micro gear pumps and peristaltic tube pumps, play a crucial role in fluid handling processes across various industries. These pumps offer precise flow control, versatility, and gentle fluid handling, ensuring efficient and reliable operations. Whether it’s accurate dosing in pharmaceuticals or sterile fluid transfer in bioprocessing, these pumps provide the necessary control and performance. As technology advances, flow rate pumps will continue to evolve, meeting the ever-growing demands of fluid handling in diverse applications.