Produkt

Oem Peristaltic Pump

Kort beskrivning:

1.Oem Peristaltic Pumps can achieve precise control of extremely low flow rates to ensure high repeatability of experimental and production processes.

2.Används för HPLC (högpresterande vätskekromatografi) provförbehandling, automatisk titratorreagensleverans, etc., för att säkerställa noggrannheten och stabiliteten hos analysresultaten.

3.Används ofta i olika kemiska synteser, biologiska reaktioner, provbearbetning och andra experimentella operationer för att förbättra experimentell effektivitet och datatillförlitlighet.

Skicka e-post till oss

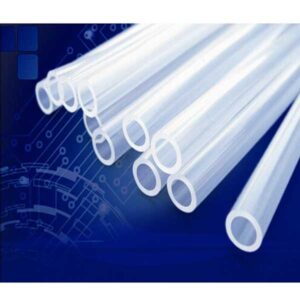

Oem Peristaltic Pump, also known as juice pump, rotary Oem Peristaltic Pump or Oem Peristaltic Pump, is a device that transports liquid by squeezing soft tubes. Its working principle is similar to the peristalsis of the human intestine, where liquid is squeezed and pushed in the soft tube to achieve transportation. Oem Peristaltic Pumps do not require mechanical seals, thus avoiding the risk of leakage and contamination.

Advantages of Oem Peristaltic Pumps

Oem Peristaltic Pumps have many advantages over traditional centrifugal pumps and plunger pumps:

- No leakage: Since no mechanical seal is required, Oem Peristaltic Pumps avoid the risk of leakage, and are particularly suitable for occasions with high requirements for liquid purity.

- Low maintenance cost: The maintenance cost of Oem Peristaltic Pumps is low, and only the pipes need to be replaced regularly, which is easy to maintain.

- Accurate metering: Oem Peristaltic Pumps have precise flow control and repeatability, and are suitable for applications that require precise metering.

- Strong self-priming ability: Oem Peristaltic Pumps have good self-priming performance and can be easily started and operated at low pressure.

Application of Oem Peristaltic Pumps

Oem Peristaltic Pumps are widely used in various fields:

- Medicine and life sciences: used to transport high-purity liquids such as liquid medicines, biochemical reagents and biological agents.

- Chemical industry: used to transport corrosive, high-viscosity and solid-particle chemical liquids.

- Food and beverages: used to transport various liquid raw materials and additives in food processing and beverage production.

- Water treatment: used for the addition, mixing and transportation of reagents in water treatment.

- Environmental protection engineering: used for liquid transportation in environmental protection projects such as wastewater treatment, gas purification and solid waste treatment.

If you have any questions, need further assistance or want more information, kontakta oss gärna. Our professional customer service team is on call 24 hours a day, looking forward to your inquiry and committed to providing you with the most satisfactory answers and services.