Product

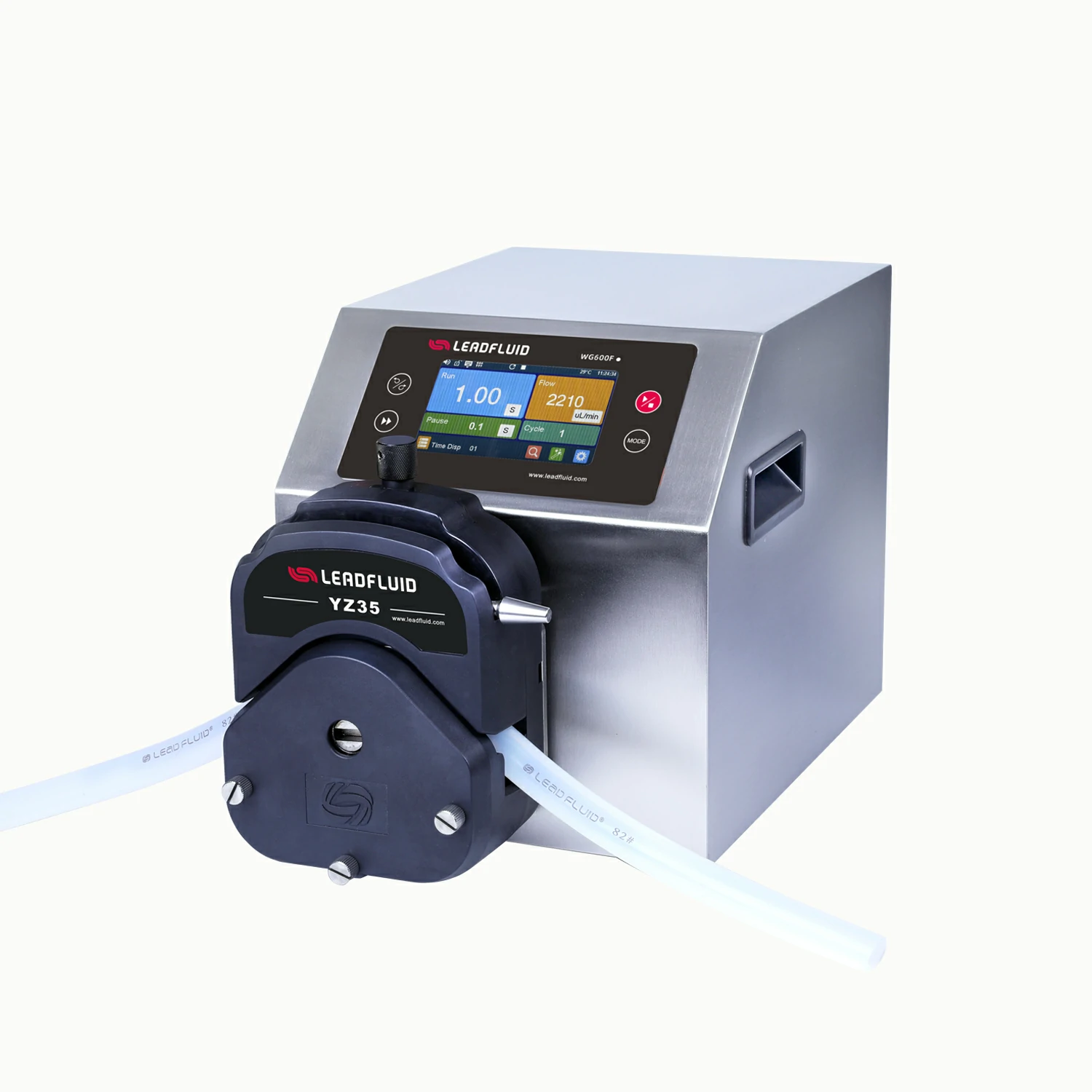

WG600F Industrial Intelligent Dispensing Peristaltic Pump

korte beschrijving:

Stuur een e-mail naar ons

WG600F Industrial Intelligent Dispensing Peristaltic Pump

WG600F industrial intelligent dispensing peristaltic pump, focuse on precise quantitative fluid transfer. Adopting a larger size and wide viewing angle IPS capacitive screen, a faster microprocessor, making operation simple, convenient, and powerful. The pump has volume dispensing mode, time dispensing mode, copy dispensing mode, and programming mode, which can achieve complex experimental processes and meet various timing and quantitative requirements; RS485 communication adds more settings on the basis of MODBUS to adapt to different communication equipment requirements.

Technische parameter

• 4.3 inch color high definition wide angle IPS capacitive LCD screen, visual.

• Touch screen cooperates with keypads operation, bring good user experience.

• External control signal supports 5-24v wide voltage input.

• Start/stop, omkeerbare richting, volle snelheid, suction function, timed start-stop.

• LF-Touch-OS software system, efficient and stable, with good human-computer interaction mode, convenient

product customization and upgrade.

• Working modes: flow rate, time dispensing, volume dispensing, programming dispensing (cycle).

• Accurate flow control and display, microstep algorithm to ensure the dispensing accuracy of different settings.

• Wizard flow calibration function, easy to use.

• Graphical pump head and tube selection, intuitive and clear.

• Flow mode supports delayed start and timed stop.

• Unique back suction function to prevent liquid drips.

• Five sets of dispensing parameters for volume and time dispensing pre-storage.

• Programming mode supports 30 different quantitative parameter settings for complex control processes.

• Intelligent temperature control function, automatically adjusting the heat according to the environment, so that the

device is always in the best state.

• External analog adjust speed , external control start-stop ,omkeerbare richting,dispensing, external signal physical

isolation.

• RS485-communicatie-interface, MODBUS protocol is available, can set up communication parameters, convenient

to connect various of control equipments.

• Open multiple control parameters , suitable for OEM custom applications.

• The circuit board is sprayed with three anti paint technology to achieve the effect of dustproof and moisture-proof.

• Super anti-interference feature, breed ingangsspanningsbereik, acceptable for the complex

power environment.

• Innovative stainless steel housing, gemakkelijk schoon te maken, effectively prevent the erosion of various organic solvents

Technische parameter

WG600F Applicable Pump Head and Tube, Stroom

Bovenstaande stroomparameters worden verkregen door een siliconenslang te gebruiken om zuiver water onder normale temperatuur en druk over te brengen, het feitelijk gebruik ervan wordt beïnvloed door specifieke factoren, zoals druk, middel enz. Hierboven alleen ter referentie.

Dimensie(mm)