Prodott

Function and Feature

■ Lead Fluid industrial micro syringe pump G6060-1S mainly suitable for high-precision micro liquid of continuous transmission, dilution and dispensing.

■ Rated stroke 60mm, standard mode 6000 steps,microstep mode up to 48000 steps.

■ Stepper motor, backlash compensation screw assembly drive, mechanical reversal with extremely high transmission stability and accuracy.

■ Can assembly a 50ul-25ml gas tight syringe, and the linear velocity range is wider.

■ The material of the valve body and the fluid path has excellent chemical properties, adapting to various neutral and corrosive solutions.

■ It can be used in various ways, it can be controlled by external signal, it can also be controlled by PC communication or it can run automatically offline.

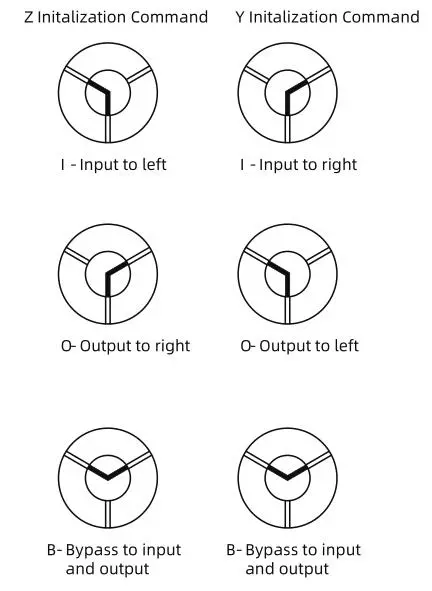

Schematic diagram(Three-port valve)

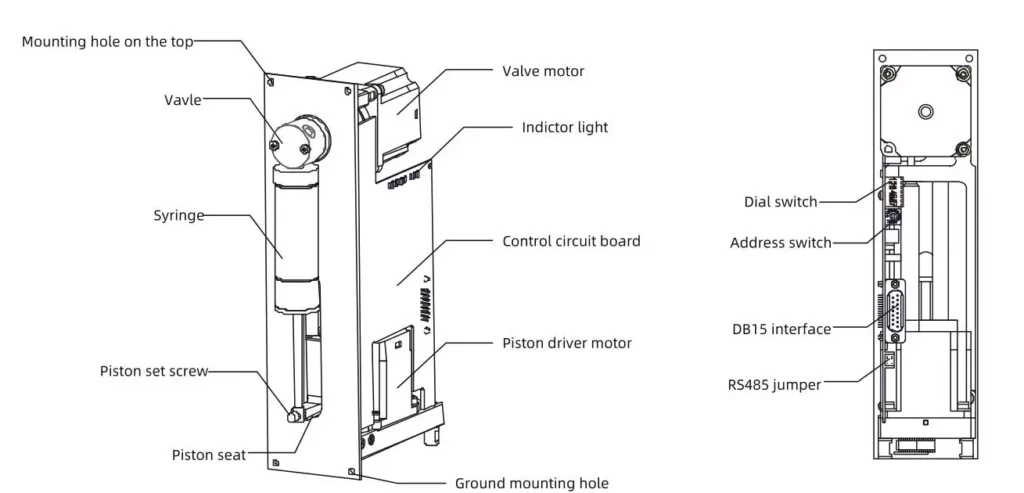

Components

SPECIFICATION

Parametru tekniku

| Linear speed | 0.01mm/s~50mm/s |

| Running time | 1.2 s~100 min(Rated stroke) |

| Flow accuracy | error≤1%(Rated stroke) |

| Flow repeatability | CV≤0.05%(Rated stroke,25℃ Deionized water,1ml and above syringe) |

| Provvista ta 'enerġija | DC 24V/2.0A |

| Syringe | 50μl/100μl/250μl/500μl/1ml/2.5ml/5ml/10ml/25ml |

| Rated stroke | 60mm |

| Control resolution | standard mode 6000 steps,microstep mode 48000 steps(rated stroke) |

| Syringe fitting | 1/4-28UNF inner thread |

| Syringe material | Borosilicate glass syringe, stainless steel push rod, PTFE piston |

| Piston drive | Steppes Motor,Backlash compensation screw assembly drive, orthogonal encoding to detect position |

| Reversing valve | standard:120°3 port |

| Valve position time | ≤250 millisecond(Between two adjacent valves) |

| Valve material | PTFE, PCTFE |

| Valve fitting | 1/4-28UNF inner thread |

| Signal input | 2 gates TTL Level signal input (drive current>16mA) |

| Signal output | 3 gates TTL level signal outpump |

| Communication | RS485/RS232 |

| Protocol | DT protocol, ODM protocol |

| Bit rate | 9600bps/38400bps can set |

| Parameter setting | 7 digit dial switch |

| Chain communication | Supports up to 15 pump communication, no converter is needed to realize the conversion of RS232 and RS485 |

| Firmware upgrade | Upgrade via computer RS232 interface |

| Programming function | Ramp, cut-off speed, gap compensation, injection speed, cycle,Real-time termination of movement and delay, error detection, valve rotation selection, storage of 15 groups of operating modes |

| Ambjent tax-xogħol | temperature 15℃~40℃,umdità relattiva <80% |

| Storage envirionment | -20℃~65℃ |

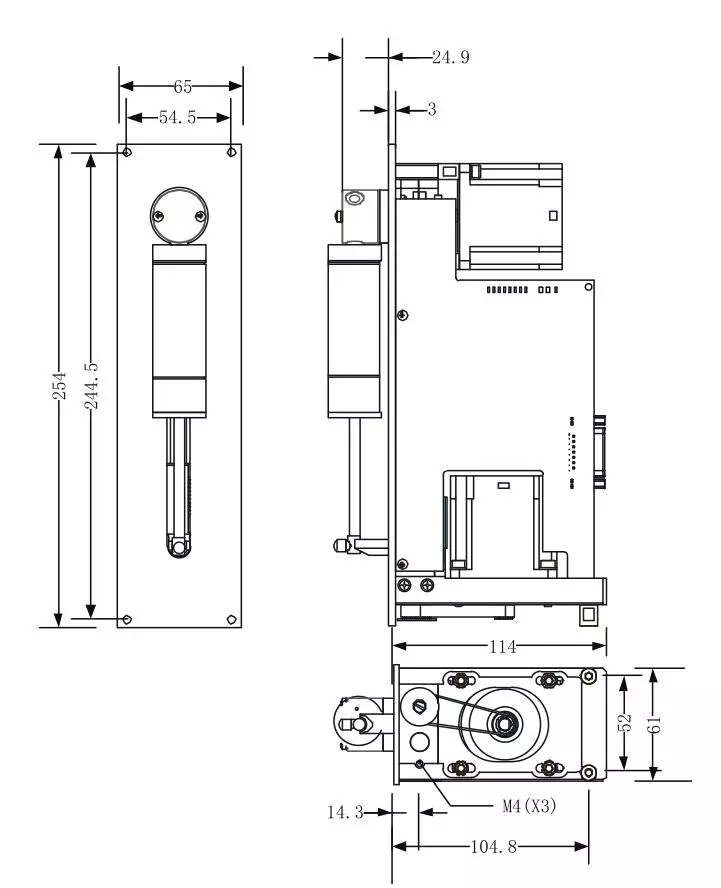

| Dimensjoni | 114×65×254mm(L×W×H) |

| Piż | 2.1kg |

Syringe

| Syringe | 50μl | 100μl | 250μl | 500μl | 1ml | 5ml | 10ml | 25ml |

| Min Flow (ml/min) | 0.0003125 | 0.000625 | 0.001563 | 0.003125 | 0.00625 | 0.03125 | 0.0625 | 0.15625 |

| Max Flow (ml/min) | 2.5 | 5.0 | 12.5 | 25 | 50 | 250.0 | 500.0 | 1250.0 |

Il-parametri tal-fluss ta 'hawn fuq jinkisbu billi tuża tubu tas-silikon biex tittrasferixxi ilma pur taħt temperatura u pressjoni normali, fl-użu fil-fatt huwa effettwat minn fatturi speċifiċi bħall-pressjoni, medju eċċ. Hawn fuq għal referenza biss.

Connector and Pipeline

Thread inverted taper joint

| Speċifikazzjoni | 1/4-28UNF |

| Material | PTFE |

Transmission line

| Speċifikazzjoni | 0.5× 1.6mm | 1.0× 1.6mm | 1.6×3.2mm |

| Material | PTFE | ||

Dimensjoni

UN:mm